See what your machines actually do—all day.

Clamp a non‑intrusive Hall‑effect sensor, let AI calibrate, and get real‑time utilization insights in minutes.

No panel rewiring

Install < 15 minutes

AI-assisted insights

How It Works

Get started in three simple steps—no machine downtime required

Clamp

Attach the Hall-effect sensor around your machine's power cable. No need to open control panels or stop production.

Non-intrusive installation

< 15 min per machine

Our non-intrusive sensors detect electrical current without any physical connection to your equipment. Installation takes less than 15 minutes per machine.

Calibrate

Let our AI-assisted system learn your machine's active and idle states automatically within hours.

AI-Powered

Advanced machine learning algorithms analyze current patterns to establish accurate thresholds. No manual configuration or guesswork required.

See

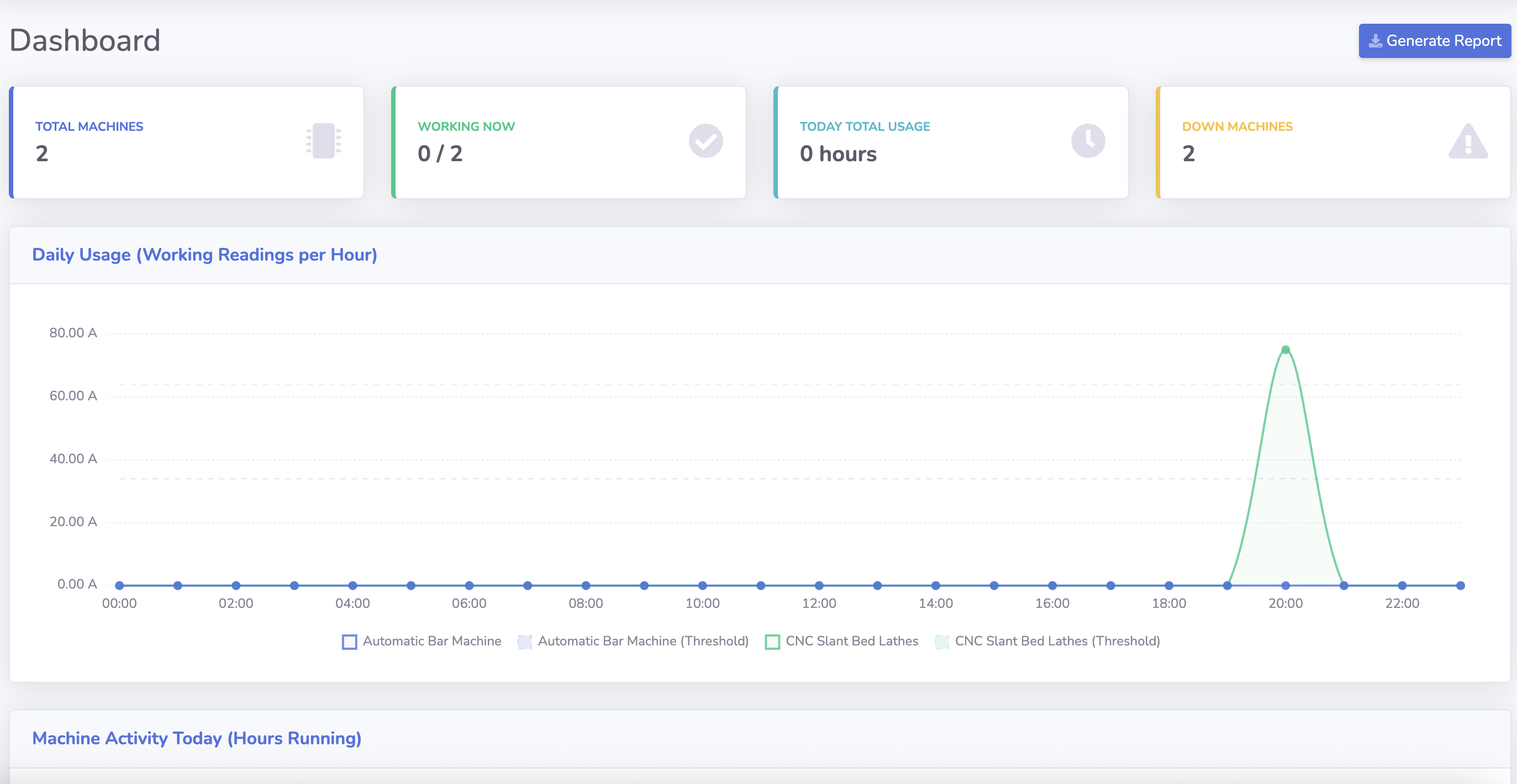

Access real-time utilization data, downtime analysis, and actionable insights through your dashboard.

Real-time tracking

Downtime forecasting

Track machine performance, identify bottlenecks, forecast maintenance needs, and optimize your production schedule with data-driven insights.

Calculate Your ROI

See how much value you could recover by improving machine utilization